HİDROMEK,位于土耳其的建筑机械制造商,正在使用Loop Pro3D printer为其农业车辆生产最终使用零件。

为了减少其下降时间并避免可能发生的相关成本,捷多洛梅克(Judromek)选择在其车辆制造过程中利用3D打印,以帮助减少传统生产方法的时间和成本。

使用FFF 3D打印机循环Pro,捷多洛梅克能够制造出功能齐全的零件,而无需大量的后处理。在后处理所花费的时间减少可以降低将每一个最终用途零件实施到车辆中的成本。

Hidromek Design Studio经理HakanTelışık说:“表面质量非常好。”零件非常僵化和实用;它们是无需或没有次要后处理的。”

The HMK 130CS Soil Compactor, with end-use 3D printed parts. Video via HİDROMEK

LOOP 3D and the LOOP PRO 3D printer

Loop 3D是由土耳其3D打印机制造商建立的3D打印机品牌Teknodizayn. Based in Ankara, Teknodizayn has over 10 years of experience in the 3D printing industry, having operated as a reseller for a number of 3D printer and 3D scanner manufacturers. Its current portfolio includes 3D printers from UnionTech and HP, the company also supplies 3D scanners from Artec.

With a decade of experience, the Teknodizayn team decided to create its own 3D printer through the LOOP 3D brand. Based on practical know-how, the 3D printer addresses the requirements customers in verticals such as heavy industry, aviation, and government institutions.

The first beta model of the LOOP PRO was produced in 2017. Having gone through a series of improvements, thefinal iteration of the 3D printer被批准并在Formnext 2019trade fair in Frankfurt. An FFF system, the LOOP PRO comes equipped with a build volume of 500 x 350 x 500 mm and features a modular printhead, magnetically attachable build plate, laser-assisted print bed calibration, and material conditioning unit. Additionally, the 3D printer is equipped withLOOP 3D CLOUD这是一种与之合作开发的切片和管理软件3DPrinterOS, a cloud 3D printer software developer based in San Francisco, USA.

“我们很高兴能通过减少研发时间来支持Loop 3D等制造商,以更快地进入市场。最终结果是客户可以购买超过200,000欧元打印机的20,000欧元3D打印机。这意味着客户可以从同一价格点购买10倍的打印机,并以令人难以置信的规模和质量开始低端生产。

3D printed end-use components save time and costs for HİDROMEK

HİDROMEK initially began life manufacturing attachments for agricultural tractors. In the following years, the company started to manufacture heavy construction machinery, and since then, its product range in this field has expanded.

现在,他们的机器包括反铲装载机,液压挖掘机,车轮装载机,运动地机和土壤压实机。这些机器雇用了大约2000名员工,在六个生产设施中生产,包括安卡拉的4家工厂,伊兹密尔的1家工厂以及泰国的一间工厂。

捷多洛梅克(Judromek)试图减少制造时间的时间,以满足涉及大量投资的严格时间表。因此,该公司使用Loop Pro 3D打印机来帮助生产许多最终用途零件。

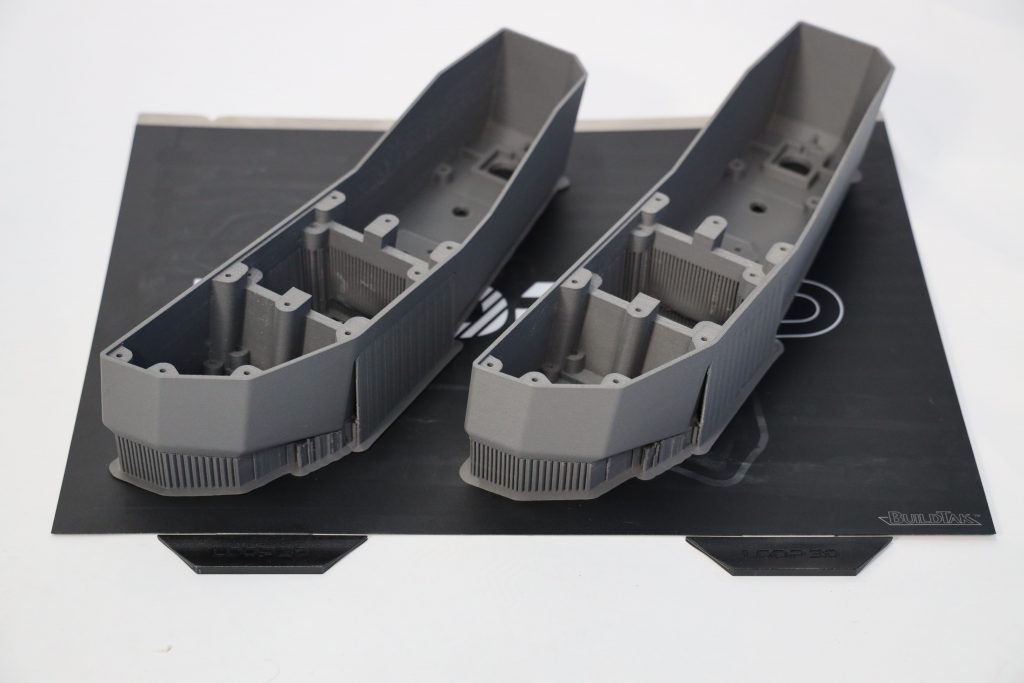

An example of an end-use component that HİDROMEK has 3D printed is the housing of the controlling unit on one of its HMK 130 CS Compact Rollers. The controlling unit houses the operator controls for the vehicle, with internal mounted electronics. In order to ensure the functionality of this critical component, the housing must meet strict tolerance and durability requirements.

The standard process for developing the housing unit is a labor and capital intensive undertaking. One stage of the design process requires the production of a master model and silicone molds. Using the Loop PRO 3D printer, HİDROMEK 3D printing the controlling unit housing at an 80 percent reduction in cost per single part.

总共尺寸为390毫米x 100毫米x 95毫米的型号,花了48小时才到3D打印,价格为54美元。由循环3D制成的零件Dynamide Carbon Fiberand Glass Fiber filaments, passed HİDROMEK’s certification tests for direct use in the company’s heavy-duty vehicles.

“我们很荣幸能与重型汽车行业和Hidromek合作,这是我们Dynamide©碳纤维和玻璃纤维材料的挑战性测试 - 由于Loop 3D的硬件和软件的结合,我们成功通过了另一个测试。LOOP 3D软件具有直观且用户友好的界面,模型准备工作是不到几分钟的。与3Dprinteros合作以实现这一目标很高兴。” Loop 3D联合创始人ErkanUstaoğlu说。

The nominations for the2020 3D Printing Industry Awards现在开放。您认为谁应该在今年的演出中列出入围名单?现在有发言权。

Subscribe to the3D打印行业通讯for the latest news in additive manufacturing. You can also stay connected by following us onTwitter并喜欢我们Facebook。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。