跟随acquisition of Freshmade 3D’s patented 3D printed tooling今年早些时候的技术,Binder Jet 3D打印机OEMExone现在已经推出了自己的3D打印工具产品组合。

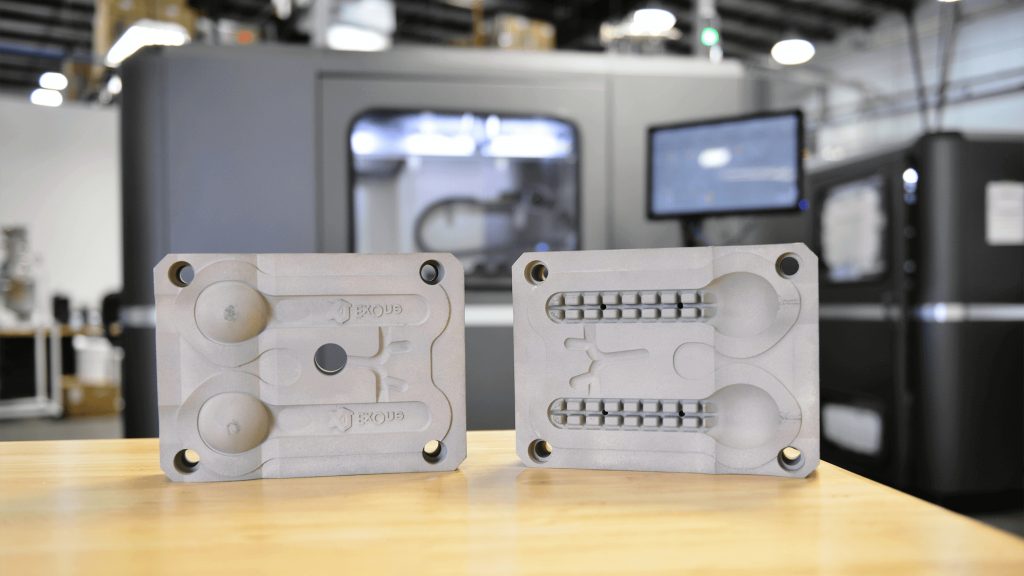

据报道,针对制造商的X1 Tooling系列是世界上最大的工业级3D印刷工具产品。产品线包括用于塑料注塑,形成,复合上型,金属铸件等的工具。

约翰·哈特纳(John Hartner), CEO of ExOne, said, “Today’s launch of the X1 Tooling portfolio is the direct result of strong customer demand for tooling options that speed up delivery times and bring tooling closer to the point of final production, wherever that is for them.”

客户可以直接从Exone的收养中心之一购买新的Binder Jet 3D打印X1工具产品。

聚合物,复合材料和金属

对于聚合物生产应用,X1工具范围包含X1 MetalTool和X1热膜。前者有420i钢制,316升不锈钢,M2工具钢等,旨在替换钢或铝制工具,用于塑料注塑成型和吹塑塑料。另一方面,X1 Thermoform是一种3D打印的砂形式,并用加固树脂浸润。它可用于一系列热成型应用,例如真空形成,压缩模具和泡沫成型。

When it comes to composite production, customers can make use of X1 Layup and X1 Washout. X1 Layup is a custom 3D printed sand form specially designed for high-precision, high-temperature composite layup applications. It offers dimensional tolerances of +/- 0.025” and the 3D printed tooling can also be CNC machined to +/- 0.005” if needed. X1 Washout is a sand form made of a water-soluble binder. Intended for ducting, mandrels, and other trapped shapes, the sacrificial form can be washed out with water after traditional composite layups and autoclaving.

X1 Tooling also contains products for metal part production. X1 SandCast can be 3D printed in a range of sand types and binders, and is designed primarily for custom aluminum castings. X1 DieMold is still in development but can be 3D printed in H13 tool steel for high-strength and durable die molds. It’s worth noting that X1 MetalTool (for polymer production) can also be used to 3D print metal end-of-arm tools, as well as consumable cutting tools.

Hartner adds, “As the COVID pandemic has continued disrupting supply chains, we’ve had more and more manufacturers ask us: ‘Can you 3D print tooling?’ Today, we’d like the market to know that the answer is yes — we can help de-risk your supply chains and make them more sustainable, with less shipping and other forms of waste. Our new tooling portfolio is a grand slam of fast and affordable new tooling options for manufacturers.”

Celwise ABand X1 MetalTool 316L

许多Exone的客户已经开始使用该公司的3D打印工具产品,包括基于瑞典的环保包装公司Celwise AB。Specifically, Celwise is using 316L stainless steel X1 MetalTool 3D printed by ExOne to transform wood-based materials into water-resistant molded fiber products. The company’s cups and food containers are designed to replace single-use plastics and look and feel just like the real thing.

“Our planet needs this technology now,” said David Pierce, Inventor and Co-owner of Celwise. “Our patented technology delivers a recyclable, renewable, and biodegradable product that can be manufactured faster and more affordably than traditional technologies. Advanced manufacturing approaches, which rely on 3D printed tooling from ExOne, are an important part of our process.”

Earlier this year, Italian luxury jewelry supplier Promotion SpA adoptedIntamsys3D printing technology to开发自己的一套定制珠宝工具。该公司能够创建强大的新手镯对准工具,能够承受多个测试周期,而无需刮擦产品的精细外观。

别处,前进, the 3D printing arm of chemical company巴斯夫, has previously launched its own超快17-4 pH金属丝专门用于3D打印的工具应用。17-4不锈钢材料包括聚合物基质中的金属粉末,旨在在最常见的FFF系统上实现安全且具有成本效益的金属印刷。

订阅3D打印行业通讯for the latest news in additive manufacturing. You can also stay connected by following us on推特, liking us onFacebook, and tuning into the3D Printing Industry YouTube Channel。

Looking for a career in additive manufacturing? Visit3D打印作业在行业中选择一系列角色。

Featured image shows X1 MetalTool used for a 3D printed plastic injection molding application. Photo via ExOne.